I’ve been working on my 911 and 356 suspensions back to back and the comparisons are interesting to say the least!

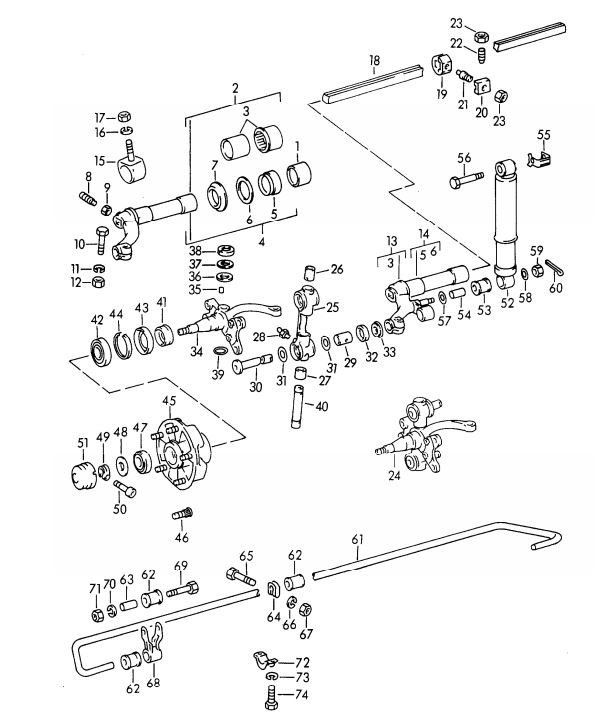

I counted 168 parts on the 356 front suspension. (Way more if you count individual needle bearings!)

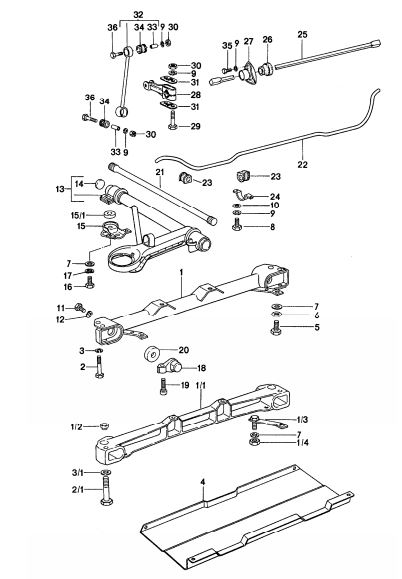

Porsche’s 911 has around 80 parts! That’s HALF the parts count.

Porsche’s designers evolved their design with disposable components like ball joints and rubber bushings on the 911 while the 356 components all require a “rebuild”.

I guess you could say that the bronze link and king bushings are disposable, but you can’t exactly just bolt new ones in. They require specialized presses and reamers to make them fit! Ask me how I know.

356 Suspension Rebuild Versus 911

Both the 911 and 356 eventually wear out, but the serviceability of the 911 is far more user friendly.

911

For instance, a 911 front suspension refresh typically requires replacing the rubber bushings, maybe the ball joint requires replacement, and possibly a new or rebuilt strut insert.

The rubber bushings can be accessed by removing a few bolts to break the suspension arm loose. Sometimes the torsion bar end cap can be difficult to remove as well, but not too bad. From there the rubber bushings can be heated and slid off. Then new ones pressed on. Some replacement bushings come with a threaded rod tool to squish the new bushings on.

Some specialty tools are required to remove the ball joint from the 911 but I find that the ford 4×4 hub tool works well enough.

356

In contrast, the serviceability of the 356 requires more skill, time, money, and special tools.

You won’t find any rubber isolation components on the 356 suspension except for the sway bar mounts to the car.

All the suspension pivots are hard, such as Phenolic/Nylon bearings, roller bearings, or bronze sleeve bearings.

All of these bearings require special tools to remove and replace. Then, once they are pressed in they will require custom reamers to size. (King pin and inner torsion arm pivots, specifically).

It’s not uncommon that the 356 C link carrier has some wear if routine maintenance was ignored. This requires special grinding to restore the contact faces to be perpendicular with respect to the link pin bores. I did this work myself here.

Some shops offer a rebuild or exchange service for the 356 suspension component rebuild because the process is pretty intense. If you do it yourself, DIY, then be careful with your press as you will need a few tons of pressure to restore these parts. Often times expensive parts can be damaged by the press.

Since the Porsche 356 is a welded monocoque chassis construction the front torsion tubes are not replaceable or adjustable as they are with Volkswagen. This means even more tooling is required to ensure the chassis’ torsion tubes are parallel and in the correct place.

My car in particular has had some rust repair done in which the heat can distort the locations of the front suspension attachment points.

The tolerance for the tube parallelism is .031″! That is pretty darn precise. If you want to watch me struggle bringing my car back into specification with the use of some custom machined inner bushings, click here.

Factory Costs To Produce 356 VS 911

Precision of the 356 suspension assembly is pretty tight because without thick rubber bushings in place the 356 suspension can bind if not in good condition or properly setup.

This precision means extra cost to produce and maintain. Consider the cost of the 356 components of the 911

- Forged carriers and trailing arms versus the stamped steel arms on the 911

- Needle roller bearings on the 356 versus rubber bushings on the 911

- Grease fittings everywhere versus maintenance free components on the 911

I’m amazed how Porsche made any money during the 356 era production. With double the parts count and expensive forging tools the factory profit margins must have been low.

I would LOVE to listen in to the design versus cost considerations in the mid 60’s.

356 Versus 911 Suspension Maintenance

Porsche’s 356 factory workshop manual recommends greasing the front suspension points every 3000 miles, however many of the shops that offer a rebuild service suggest 1500 miles and even more frequently if driving in dusty or wet conditions.

You can’t even drive a 356 across the country without pumping grease in there. If you drive through rain, then Porsche recommends to add grease right away to pump the water out! I highly doubt people did this when the cars were new, ha ha. Who wants to drive around with a grease gun?

The 911 suspension is essentially maintenance free. The rubber bushings are designed to flex instead of rub material off each time your car hits a bump. The ball joints are made to last and sealed at the factory. Once the ball joints do wear out, you simply discard them and bolt new ones in place.

Which One Performs Better 356 Versus 911 Geometry?

Porsche’s design continues to evolve and improve each year it seems. The 911 geometry is far superior when cornering versus the 356 trailing arms. One nice feature of the Macpherson strut design is that the camber goes more negative and the suspension travels up. This helps keep the tires contact patch more constant as the body and tires roll at high cornering forces.

The 911 also has more adjustability and alignment options to dial in caster and camber whereas the 356 is pretty limited without major parts modifications.

356 engineers went through great lengths to make a supple yet precise suspension. It may even be more precise than the 911 when it was new. There is no opportunity for rigid bearings to distort or flex under load.

The 911 rubber bushings provide some isolation to the chassis for a less harsh ride if crossing a cattle grate for example.

The ultimate performance is to take the rigid bushing design from a 356 and install a similar product on the 911.

In fact this is what I’ve done on my 911. I installed Rebel Racing Products Teflon bearings in place of the stock rubber bushings. Click here to see that video.

These hard teflon bearings provide the same maintenance free operation as the rubber ones, but they don’t allow the suspension arm to deflect during or cornering. They also dramatically free up the suspension travel. A WIN-WIN if you ask me.